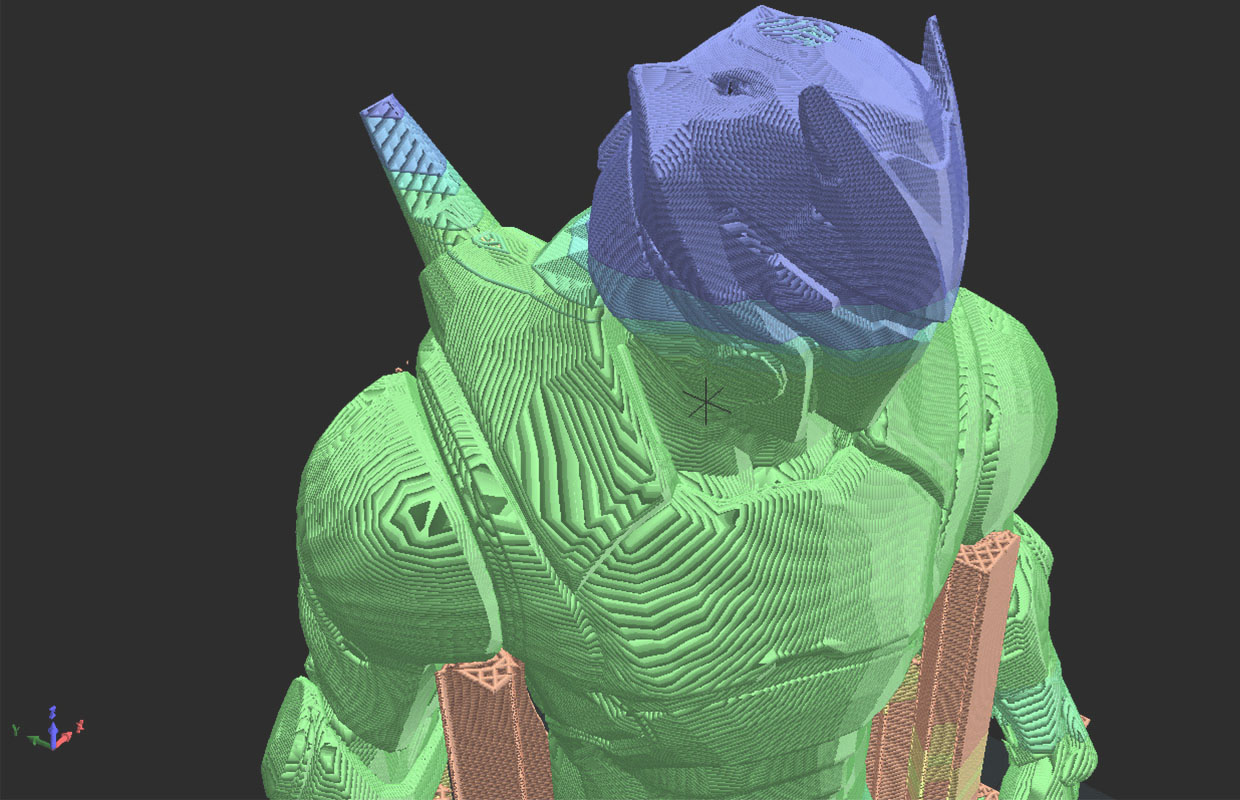

3D Modelling

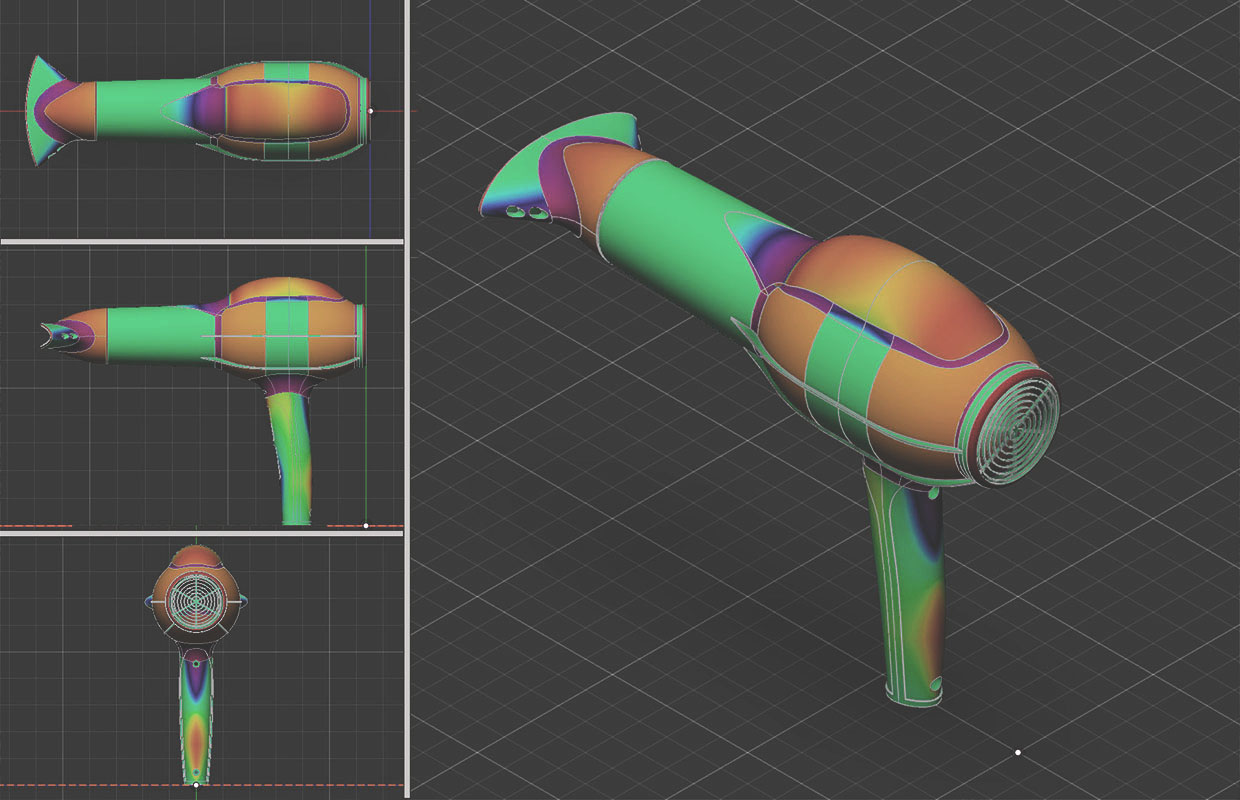

Infillcube’s in-house master craftsmen are always ready to shape up your ideas. Our team of 3D modelling engineers will assist you in creating quality 3D models as per your industrial demands. The valuable insights we gained by catering to numerous industries and diverse customer requirements have prepared us for any complications. Our team of experts are well versed in 3d rendering and texturing. We ensure that with the help of high quality image and video renders, you will be able to create the effectiveness and photorealism demanded to meet the standards for modern day advertisement and campaigning.

Aside from the aesthetics we also give uttermost priority to how the product will perform in the real world scenarios. We provide finite element analysis which will predict failure possibilities and helps to iterate through design changes. This gives a huge head start for the customer in the competitive market.

- 3d Modelling

- 3d Rendering

- Simulation Studies

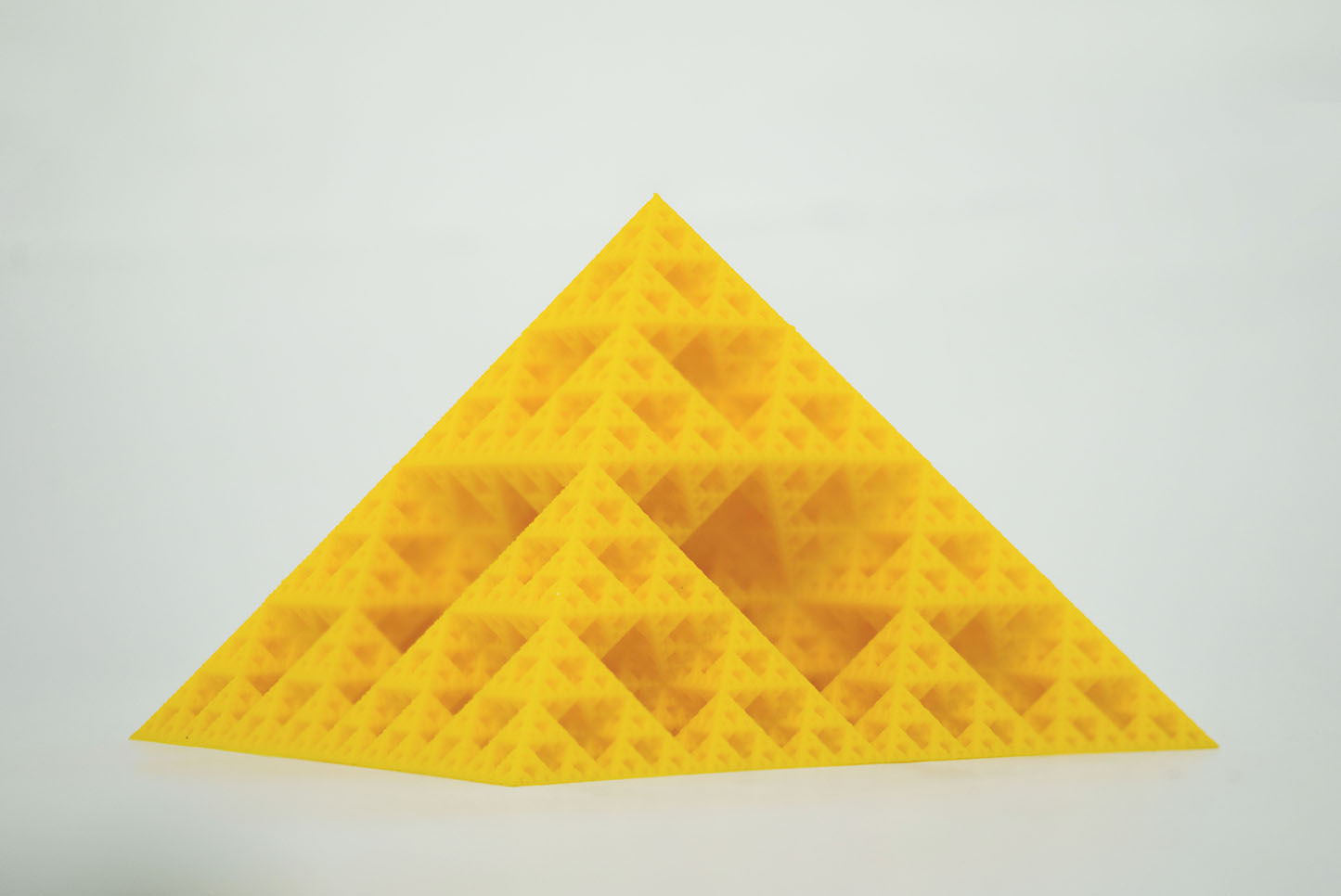

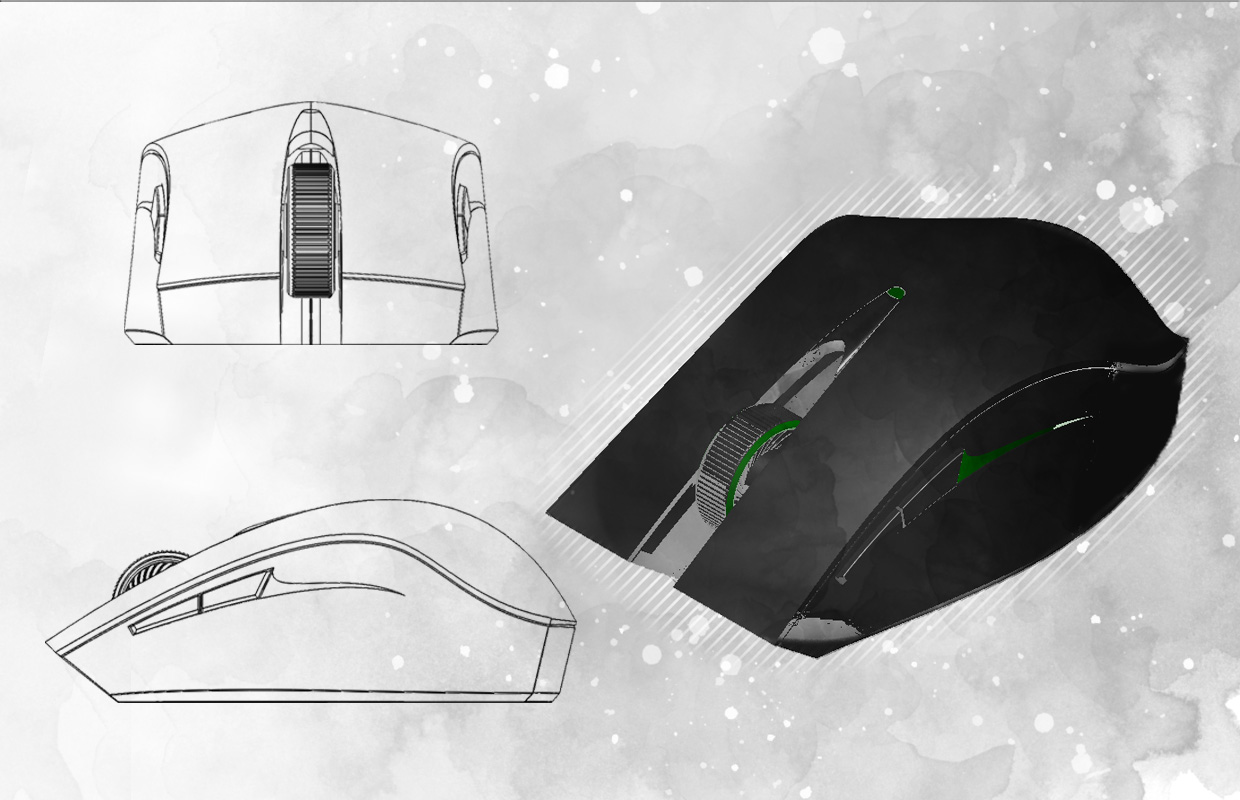

3D Printing

3D Printing is a digital fabrication technique by which you are able to create a physical object from a 3D CAD model. Whether you are an organization or simply an enthusiast, you can tap the full potential of additive manufacturing by making use of Infillcube 3D printing services.

If you don’t have a plan to buy a 3D printer and is in search of the next best solution, you can avail our 3D printing services with minimal investment. Our Smart and Industrial grade printers are capable of providing accurate, fast and reliable 3D prints. You will have an option to choose from a plethora of materials and colours most suited for the product. Our craftsman will be on hand to assist you from the moment you upload the model, and until the product is delivered at your doorstep.

Product Development

The Infillcube team takes special care of your dream by being a part of the journey from the designing stage until the successful launch of the product into the market. Our end of the day goal is to provide quality services to the customer within a minimum budget. Our product development team will ensure that the time-to-market will be at the bare minimum, which will make the end product a front-runner in today’s competitive market.

Once we have the blueprint of the product, our team will proceed to choose a design which combines efficiency with market viability. Since we always adheres to DFM designing methodology, there won’t be any hassles in later stages of manufacturing. After ensuring the customer is happy with the 3D model, a prototype is then built. Our Quality team will then validate the prototype and push on with the manufacturing process with regard to the customer’s unique demands.

- 3D Modelling and Prototyping

- Design for Manufacturing Optimization

- Manufacturing assistance

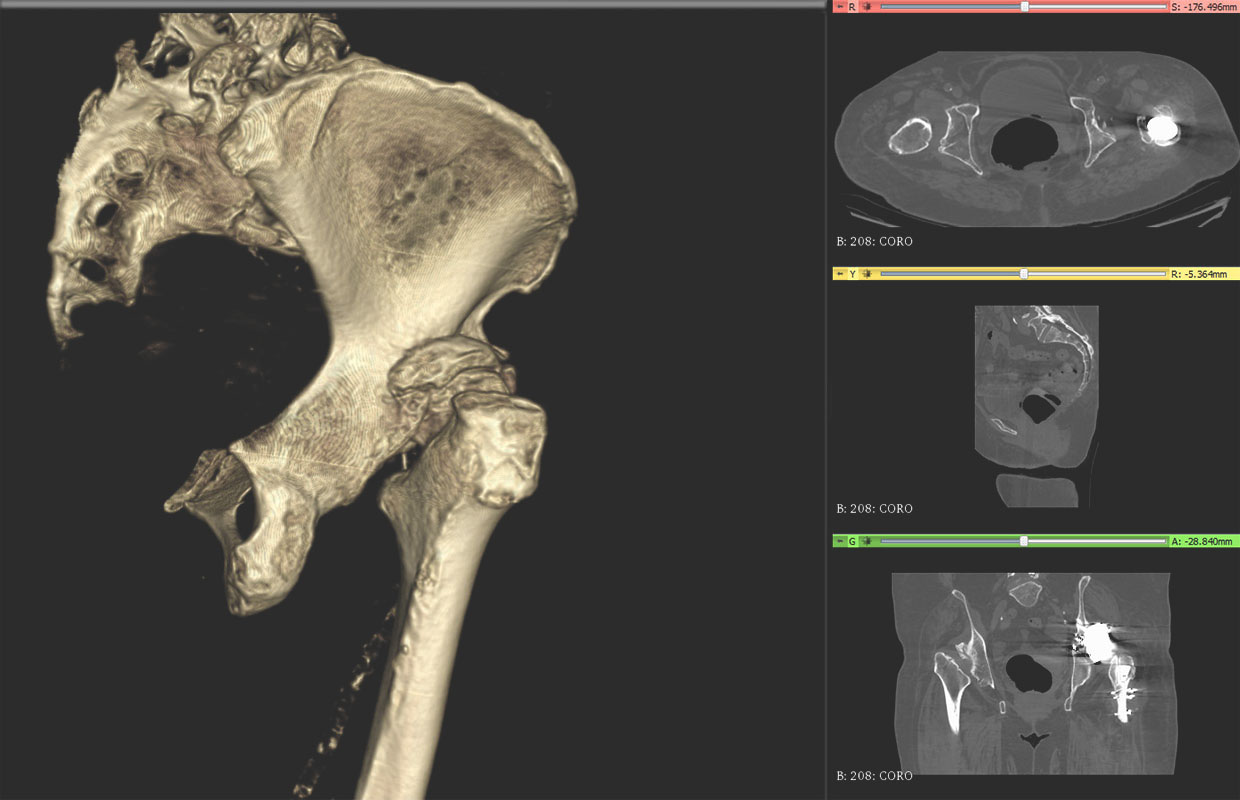

Surgical Modelling

The rise of 3D Printing has been prominent in the medical field too. Keeping that in mind, Infilcube has extended its service by providing a real-life scaled model of a patient’s anatomy, once our team gets hold of the data from medical imaging.

Based on our precise physical model, the medical practitioners can get familiarized with the task at hand. This further ensures that there won’t be any unanticipated complications during the actual process. The implementation of this technique will help to minimize the blood loss and trauma endured by the patient during the surgery. In addition to this, we also provide services like the production of custom jigs and guideways, prosthetics and tailor-made accessories.