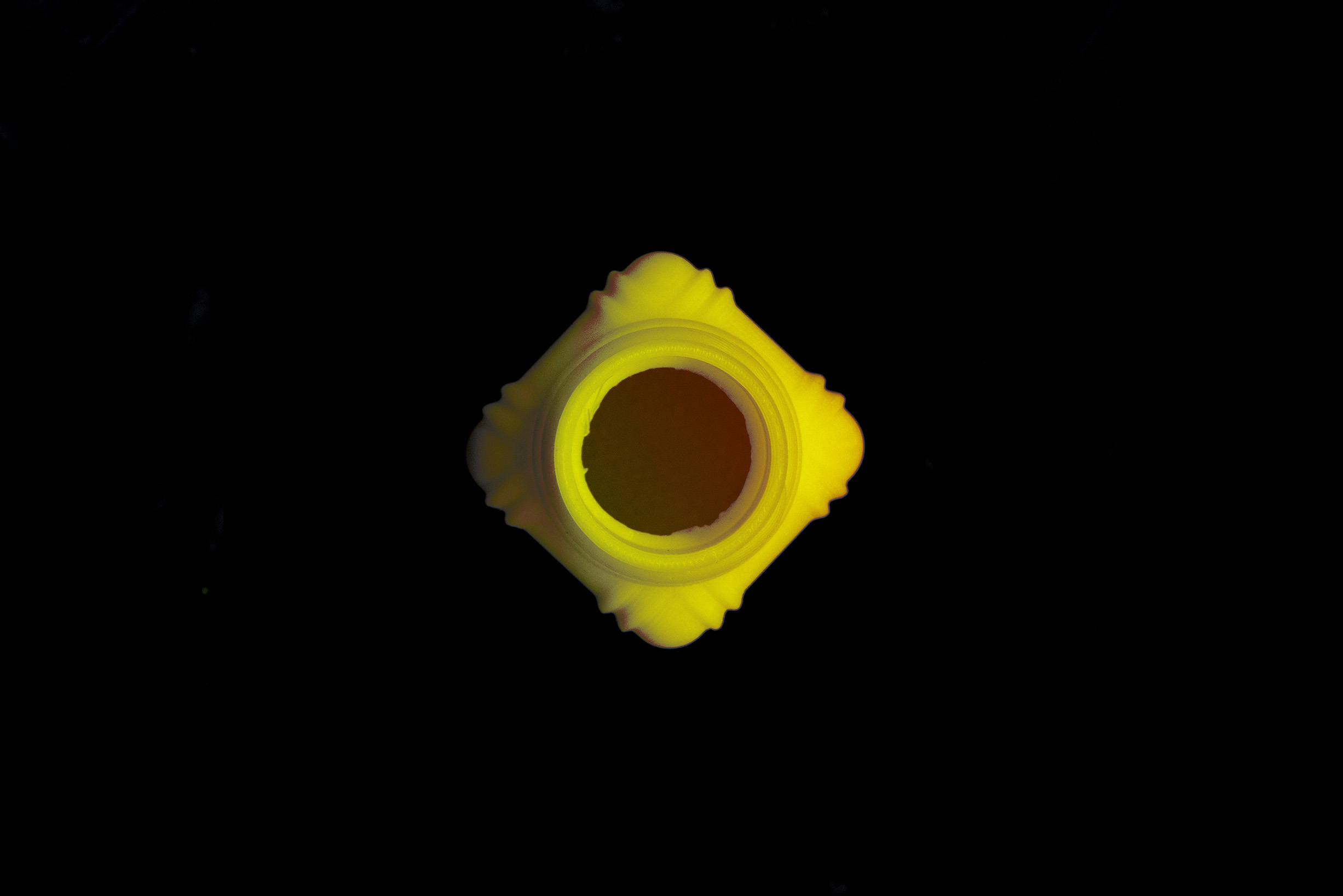

The advances in prototyping using additive manufacturing has made the development of consumer goods easier and accessible. Customers can now validate the output before it goes into production and there is a significant reduction in the overall turnaround time for mold manufacturing

The presence of 3D printing spectrum gives the designers the freedom to easily iterate through variations. Wherein time and material wastage in the segment is managed considerably well in the early stages till production. The capability of Infillcube 3d printers to reproduce models of any scale, with precision, have made the prototyping of even smallest goods a success story.